C.G. Laboratories, Inc. offers specialized guidance and comprehensive services for E-Beam Sterilization Validation, ensuring the effective sterilization of medical products through ionizing radiation. E-Beam is more powerful, leading to shorter exposure times for devices being sterilized.

E-Beam Sterilization

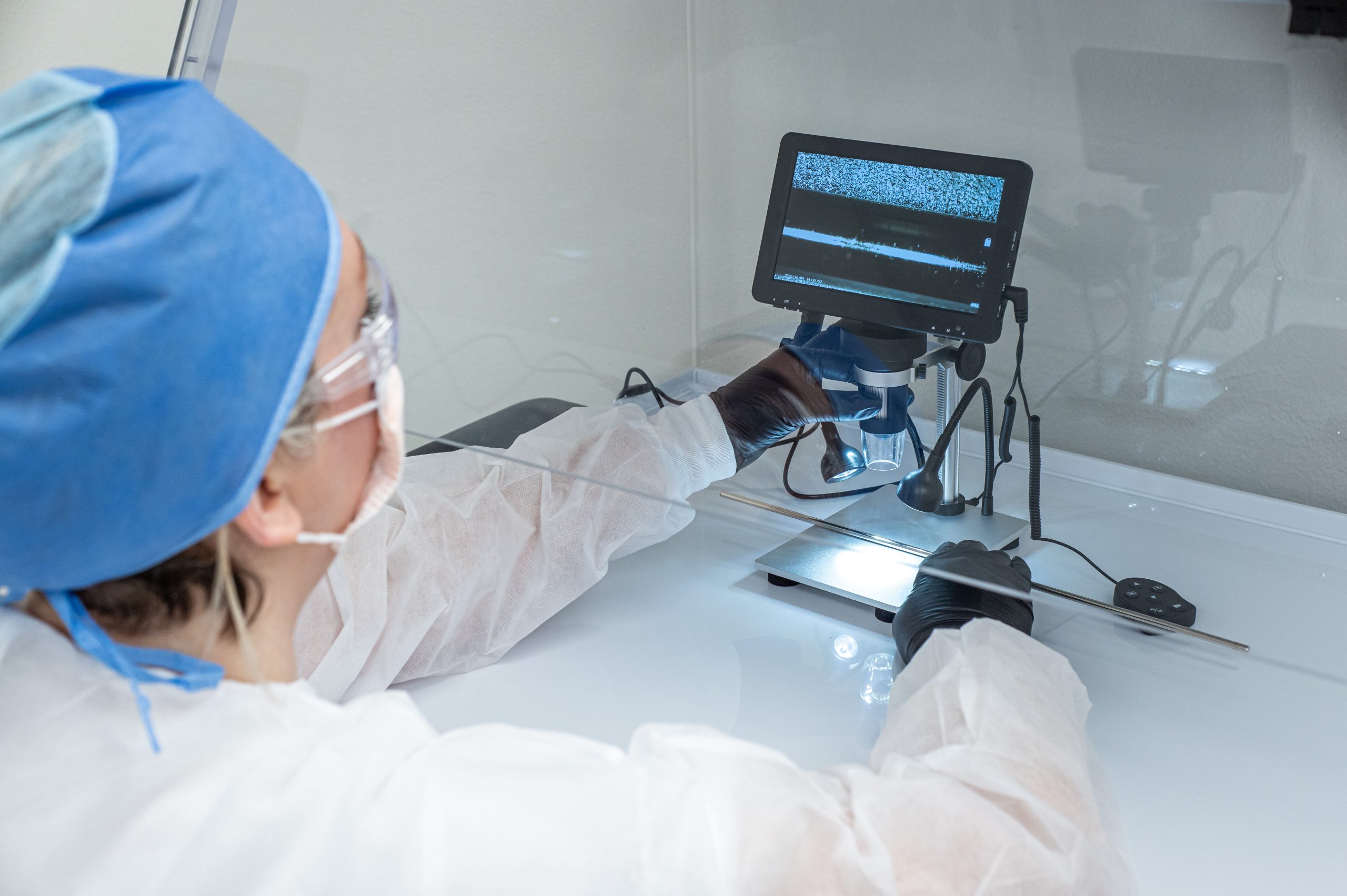

E-Beam sterilization uses high-energy electrons to create free radicals, effectively altering and destroying microorganism genetic material. It is gentle on product material and packaging compared to gamma sterilization and is compatible with most materials. However, it may have reduced penetration for dense products or those with varying densities.

Tests Performed

- Bioburden

- Bioburden Recovery

- Bacteriostasis/Fungistasis

- Sterility Testing

Request Information

C.G. Laboratories, Inc.

(817) 279-1945

Why Choose CG Laboratories?

C.G. Labs began in 1983 as a microbiology laboratory founded by Dr. Glenn Crum. In 1996, we relocated to Granbury, TX and expanded our services to include medical device contract manufacturing. We have grown into a multi-service company with three distinct divisions with 19,000 square feet spanning two sites. All our services are current, regulated and quality-driven. We are registered with the FDA and ISO accredited to 13485:2016 and MDSAP.

Our GET MORE objective gives you great customer service, guidance, quality management and access to experts. We strive to exceed your expectations, to meet government regulations and to make the world a safer place. With C.G. Laboratories, you always GET MORE.

Sterilization Validation Process and Methods

C.G. Laboratories ensures accurate and efficient testing, including Quarterly Dose Audits (QDA) to maintain ongoing compliance and demonstrate continued sterility. The company provides guidance on choosing the proper sterilization dose and testing methods to meet specific product needs, offering customizable options for Method One and VDmax Method. Method One allows for a fully customizable sterilization dose but requires a large amount of product and tends to be more expensive due to additional testing. On the other hand, VDmax Method requires fewer product samples and testing compared to Method One, offering more economically viable options.